Bevel Gear, OEM Grinded Double Helical Gear, Grinded Spiral Bevel Gear Pinion Wheel

1.P roduct Description This Gear shaft, Herringbone Gear Shaft, Bevel Gear, Eccentric Shaft mainly used on vessel engine

Basic Info

| Model NO. | Large |

| Type | Bevel Gear |

| Transport Package | Export Package (Wooden Box, Steel Frame etc. ) |

| Specification | 1M-16M |

| Trademark | TOTEM/OEM |

| Origin | China |

| HS Code | 8483409000 |

| Production Capacity | 5000 T/Y |

Product Description

1.Product DescriptionThis Gear shaft, Herringbone Gear Shaft, Bevel Gear, Eccentric Shaft mainly used on vessel engine, fan internal gear

2.1. Grinded spiral bevel gear Processing

Grinded spiral bevel gear drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

2.2. double helical gear Package

Spray anti-rust oil on Bevel Herringbone Gear , Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

2.3. OEM Customized Gear Shaft

We supply OEM SERVICE, customized herringbone gear shaft with big module, more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material gear shaft.

2.Product Technical info.

| Module | m | Range: 5~70 |

| Gear Teeth Number | z | OEM by drawing's technical parameters |

| Teeth Height | H | OEM by drawing's technical parameters |

| Teeth Thickness | S | OEM by drawing's technical parameters |

| Tooth pitch | P | OEM by drawing's technical parameters |

| Tooth addendum | Ha | OEM by drawing's technical parameters |

| Tooth dedendum | Hf | OEM by drawing's technical parameters |

| Working height | h' | OEM by drawing's technical parameters |

| Bottom clearance | C | OEM by drawing's technical parameters |

| Pressure Angle | α | OEM by drawing's technical parameters |

| Helix Angle, | OEM by drawing's technical parameters | |

| Surface hardness | HRC | Range: HRC 50~HRC63(Quenching) |

| Hardness: | HB | Range: HB150~HB280; Hardening Tempering/ Hardened Tooth Surface |

| Surface finish | Range: Ra1.6~Ra3.2 | |

| Tooth surface roughness | Ra | Range: ≥0.4 |

| Gear Accuracy Grade | Grade Range: 5-6-7-8-9 (ISO 1328) | |

| Diameter | D | Range: 1m~16m |

| Weight | Kg | Range: Min. 100kg~Max. 80tons Single Piece |

| Gear Position | Internal/External Gear | |

| Toothed Portion Shape | Spur Gear/Bevel/Spiral/Helical/Straight | |

| Shaft shape | Herringbone Gear Shaft / Gear Shaft / Eccentric Shaft / Spur Gear / Girth Gear / Gear Wheel | |

| Material | Forging/ Casting | Forging/ Casting 45/42CrMo/40Cr or OEM |

| Manufacturing Method | Cut Gear | |

| Gear Teeth Milling | √ | |

| Gear Teeth Grinding | √ | |

| Heat Treatment | Quenching /Carburizing | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Gearbox, Reducer, Petroleum,Cement,Mining,Metallurgy etc. Wind driven generator,vertical mill reducer,oil rig helical gear,petroleum slurry pump gear shaft | |

| Transport Package | Export package (wooden box, steel frame etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

Material Comparison List

| STEEL CODE GRADES COMPARISON | |||||

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/40XHMA | 4340 | SNCM439 | 40NiCrMo6/36NiCrMo4 | |

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 | |

3.Totem Service

TOTEM Machinery focus on supplying GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission devices & equipments(large industrial reducers & drivers). Which were mainly used in the fields of port facilities, cement, mining, metallurgical industry etc. We invested in several machine processing factories,forging factories and casting factories,relies on these strong reliable and high-quality supplier network, to let our customers worry free.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

4.About TOTEM

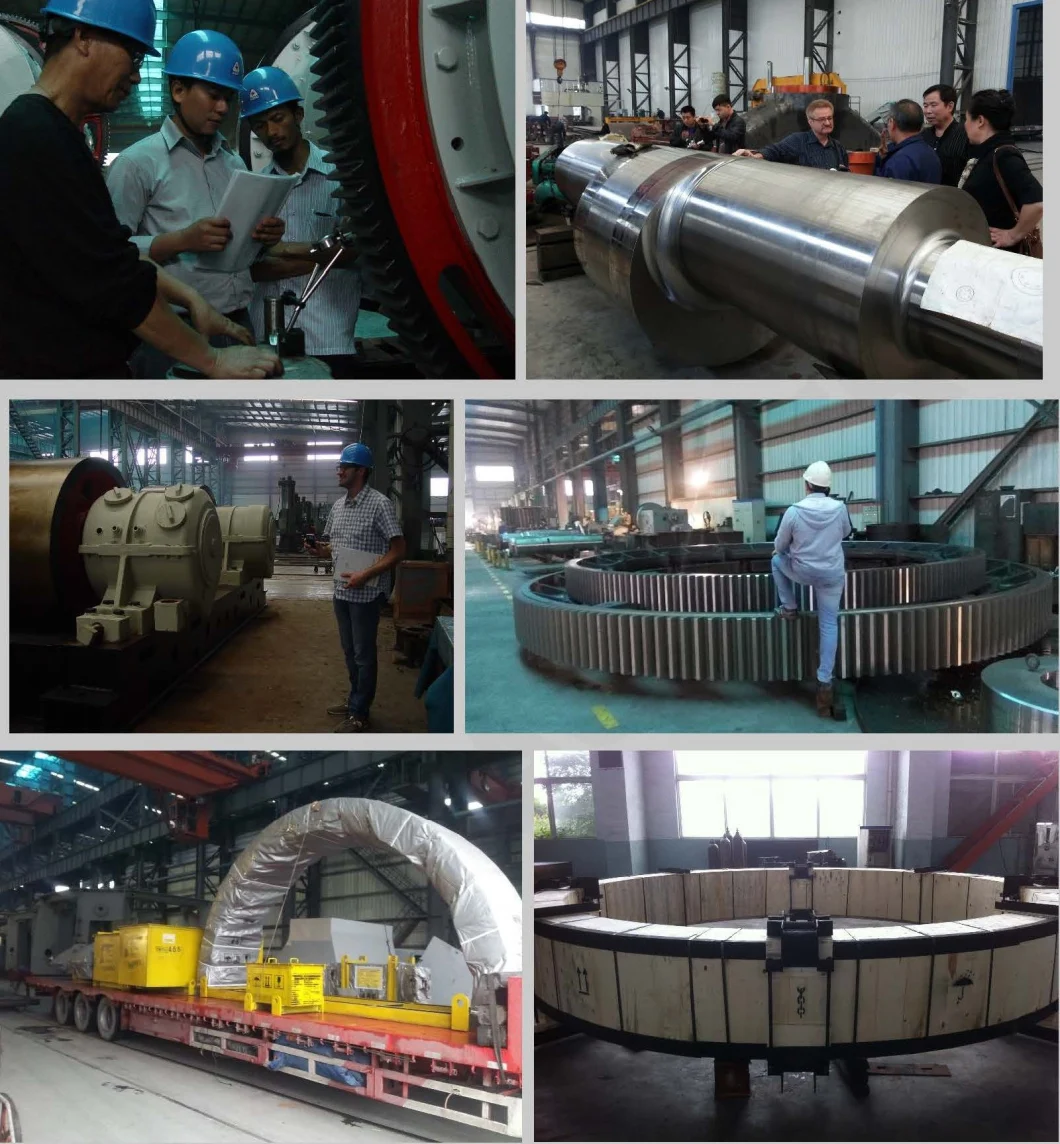

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

5. Contact UsShanghai Totem Machinery Facebook: Shanghai Totem

Send to us